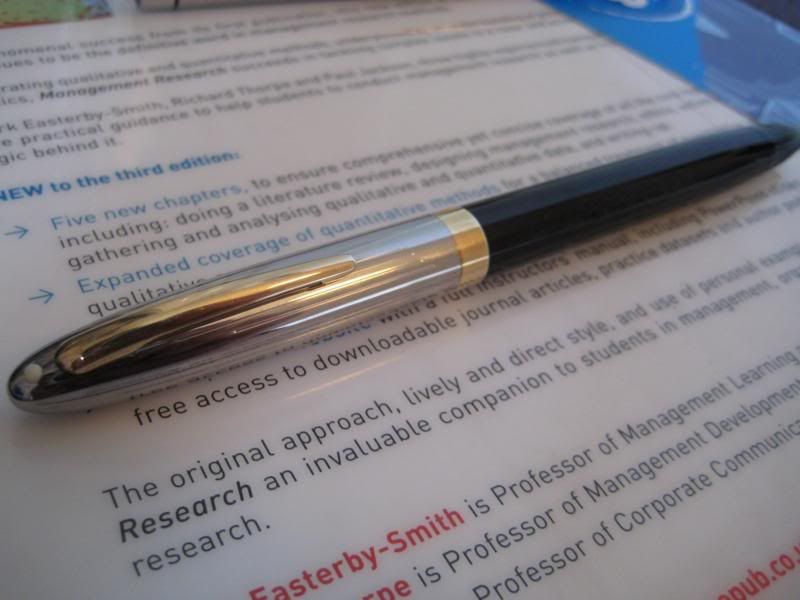

Here is my Snorkel in all its glory. Maybe a bit staid to some, to me this pen has arresting looks. Nothing screams ‘the jet age’ more than that steel cap with its bold striations. When I made my bid, it was a choice between a second hand, engraved snorkel or bidding high and early for a NOS pen & pencil set auction ending 20 minutes before my last exam. As it was, I got the used one.

As you can see, this was a pretty old pen. The nib unit and barrel started unscrewing the first time I extended the snorkel – which moved very stiffly. Whatever shellac or section sealant was used to secure it had turned to dust, just like my Targa. I thought the snorkel unit was fine when I bought it, but it soon ran out of ink! On disassembly, the spring stayed in the barrel, but to my relief there was no corrosion either on the spring or the sac protector.

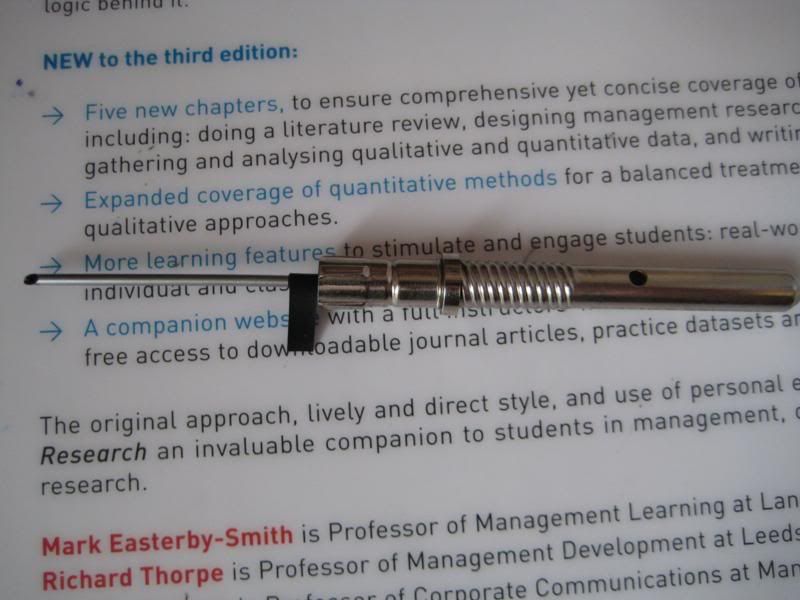

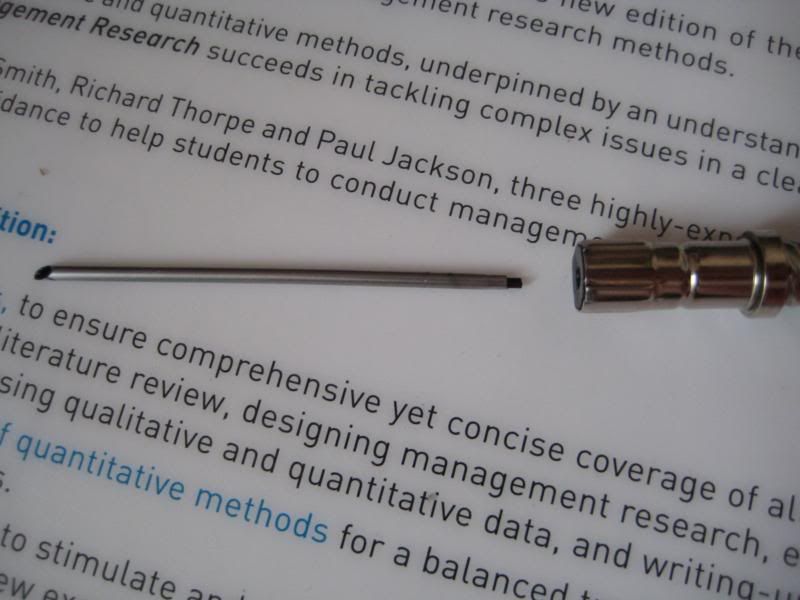

Here’s the snorkel assembly; the snorkel tube, and the sack protector. I thought I was being clever wrapping electrical tape at the end of the tube, to mark how far the tube extends into the sac protector. Of course, it slid off as soon as I picked it up after this photo was taken!

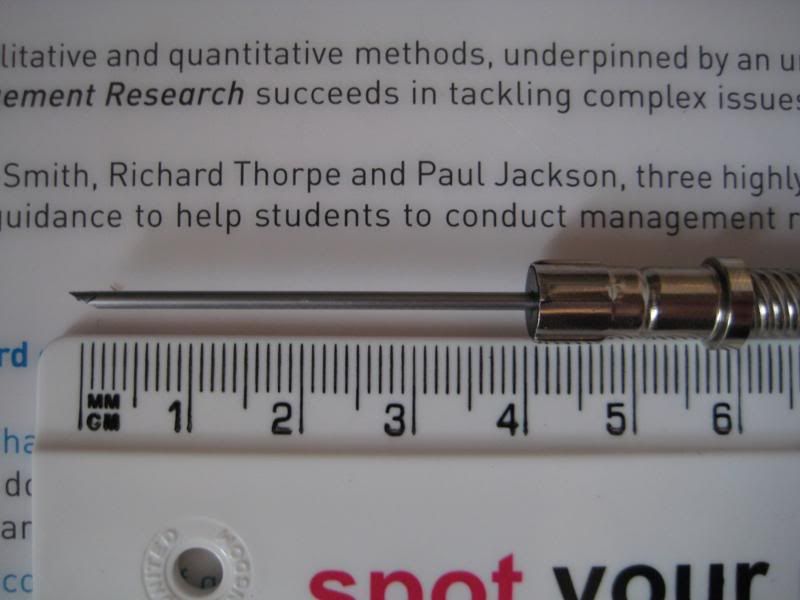

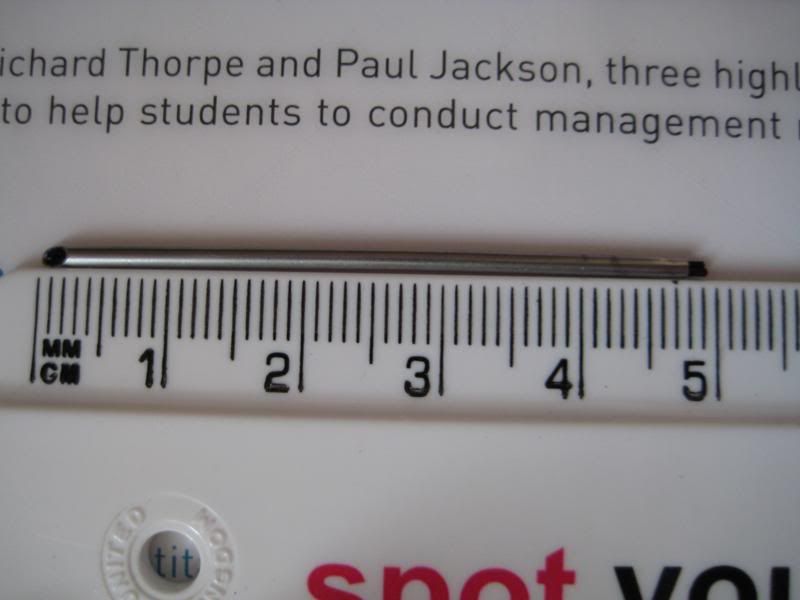

Abandoning the electrical tape idea, I set the snorkel assembly against a ruler. The snorkel tube extends a little over 4 cm from the sac protector (for my pen, anyway).

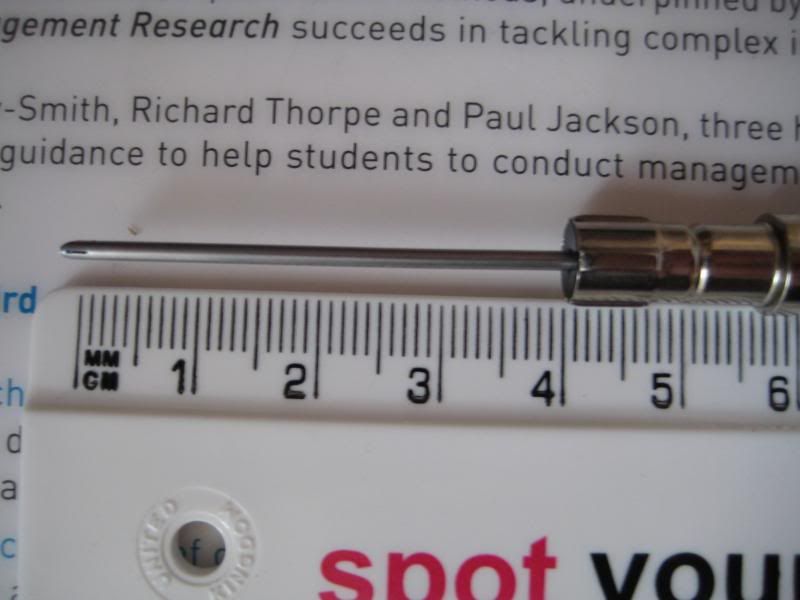

This photo shows how the top slit of the snorkel tube is positioned more or less in alignment with the the bottom edge of one of the key in the sac protector.

There’s a few divergent views on internet guides how to take the snorkel assembly apart. De-crimp the metal with a dental pick some say. Use heat say others. This was an easy decision for me; the metal is catwalk model thin, and I don’t have a dental pick. I took my pens out of their stand, plonked the snorkel assembly in it, and turned on this hairdryer.

After a short heating session I gave a cautious pull on the snorkel tube. This resulted in sore fingertips from the heat (never done this before), and the snorkel tube yanking clean out of the assembly. I will admit to a school-girlish shriek of dismay at this point.

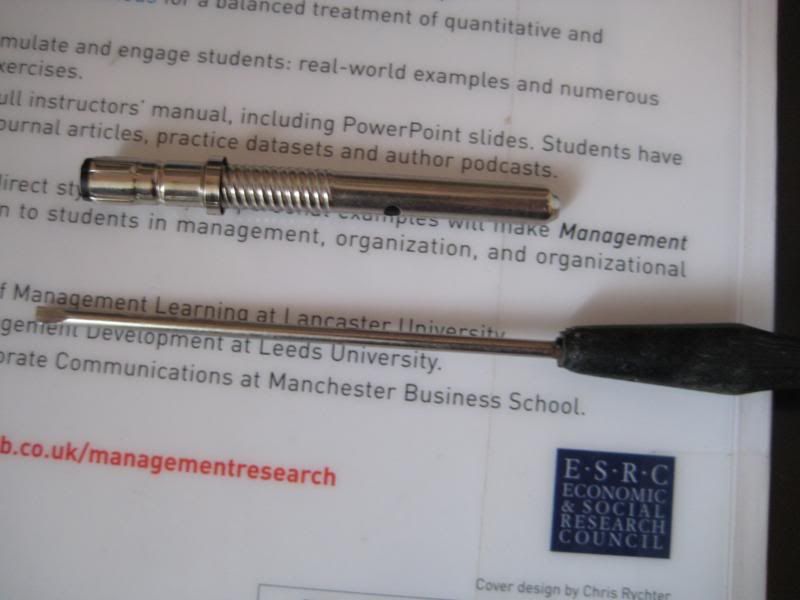

I ploughed on for the sake of science and measured the accidentally extracted snorkel. I’ve read somewhere that the secondary feed has to extend from the snorkel tube into the sac somewhat to ensure proper ink flow. Mine protudes about a millimetre.

Scrolling through my multitude of bookmarks on the subject of snorkel servicing, I reckoned it might have been a blessing that the tube came out on its own. Some advised using a metal tube inserted at the top sac protector hole to push out the rubber bung at the bottom of the sac protector, of a specific diameter, to avoid damaging the secondary feed protruding from the snorkel tube. As this was no longer an issue, and I don’t have such a tube, I resumed heating the sac protector with the hairdryer.

Here’s a shot of a hot sac protector and a long shank screwdriver I introduced to the hole in the top of the sac protector to persuade the rubber bung to extricate itself. I wrapped some electrical tape on the head of the screwdriver to avoid piercing the bung, instead of bending the head over (I didn’t want to ruin this screwdriver). The thought occurred to me much later that a small allen key might have been better, because the electrical tape kept coming off the screwdriver and getting lodged inside the sac protector.

I’d never done this before and found the results of the hairdryer remarkable. Heat had a very great influence on this bung coming out. Cold, it felt like hard plastic. Hot – 10 seconds under the hairdryer – the bung felt like malleable rubber and I was able to push the bung out with no brute force whatsoever!

I was really happy about this, beforehand I was reticent and quite sceptical of both my ability and the really thin metal to withstand crimping and decrimping over years of future sac replacement. Now it appears that, at least for this snorkel, I’ll never have to stress the steel. This shaky photo shows the bung halfway out. As the bung cooled during the photo being taken, it reverted to its previous hardness and would not budge till warmed up again.

The old ink sac remained inside the sac protector. I thought I had the perfect tool to light this photo, a little light bulb wired up to a 9 volt battery that I couldn’t find during my Targa repair. I found it this time around, but the photo still isn’t that clear! I pushed an earbud (q-tip) with one cotton bud cut off at an angle between the sac protector and the sac, and then rotated the sac protector around the earbud to loosen the old sac from the interior walls of the protector.

Then I gave up on the earbud and pulled the sac out with a little pair of tweezers. I had read that this can be a real problem with old ink sacs and was surprised this one came out with no fuss. The photo shows an exploded view of the sac protector and its innards.

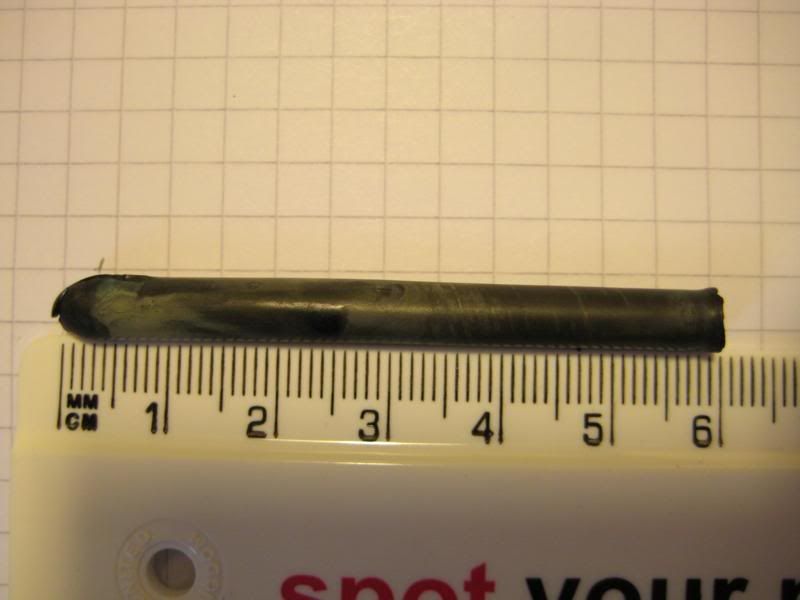

Here’s a close up of the old sac. This is my first sac change and a weird one for me. The first 1.5 cm of the sac is cracked, hard, and strangely discoloured. Then it’s flexible and black between the 1.5 and 2.5 cm marks. Then from the 2.5 to 4cm marks, it’s hard, cracked, and strangely discoloured again. From 4cm to 6cm, where the sac is shellacked to the rubber bung, it’s flexible and black again. What witchery is afoot here? Vade retro, Satan!

Wow that was a great explanation, i think i will go for it and fix my pen, thank you very much for the detail information.

ReplyDeleteDavid