|

| To the fountain pen modder looking to party like it's 1905, a Goossens spindle is indispensable. |

The ingenuity of the Goossens spindle came to me in a flash one evening. Half a minute - now I think of it, it must have been in HTML. On first reading this post on FPN, I was struck by the resourcefulness of the thing; a simple design that employs a generic o-ring, yet manages to maintain a pressure seal on the downstroke, and prevent back pressure on the upstroke. In addition, the ramping effect of the rigid cone should keep the system working even as the seal wears. The crude interpretation of the Goossens spindle as made for this mod is described below.

How it works:

- The top face of the spindle is a shallow cone. On the downstroke, this face drives the seal down the barrel, the taper ensuring a good seal as it does so. The o-ring creates an excellent pressure seal as it travels, even against the rough and unfinished interior of the Kaigelu.

- The bottom face of the spindle is also a shallow cone, but ported to allow ink and air to flow through it on the upstroke.

- That's all! "Simplicity is Beauty" etc. An elegant and pragmatic idea! Richardspens.com has a potted history of different approaches to the plunger filler back pressure issue, for a brief indulgence in technical nerdiness accompanied by neat photographs of vintage pens.

How it's made:

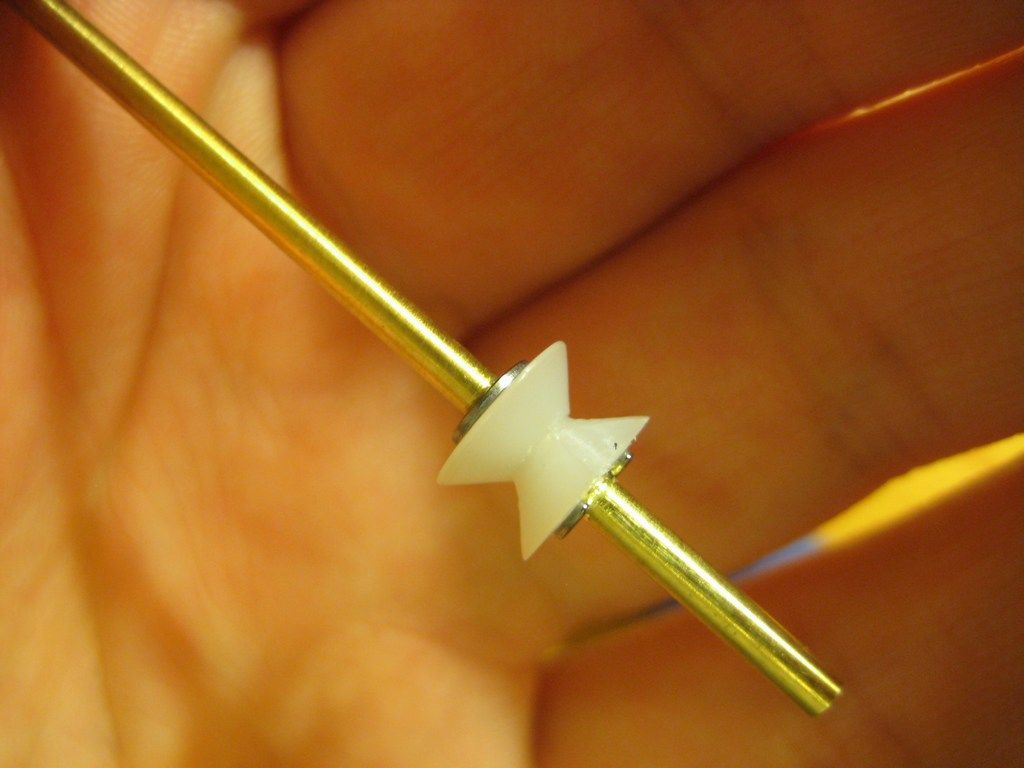

Within a few minutes of minor sawing and grinding, a commonplace plastic mini motor pulley can be reshaped to requirements, then secured to the plunger rod using stainless steel external circlips above and below. At less than £2 for a pack of 5, these pulleys come ready made with a 2mm centre hole to match the plunger rod, and an outer diameter that fits within the Kaigelu's barrel - they're ideal!

|

| An electric motor pulley to fit 2mm shaft. 1.90 GBP for an eBay 5 pack. |

|

| Discarding the cylindrical section of the pulley. This piece came in handy later on while grinding the sliding seal, as a spacer tool. |

The craft saw made light work discarding the superfluous cylindrical section, while a few seconds of holding the mini drill's grinding attachment against opposite sides of the upstroke cone face hollowed out the flow ports.

|

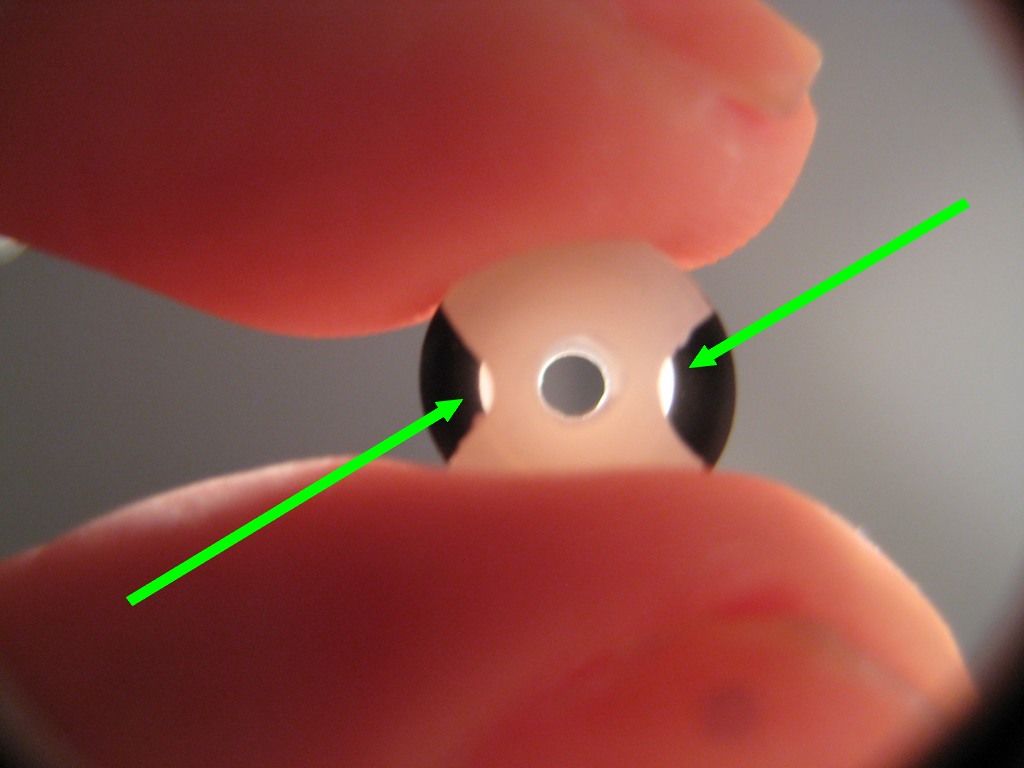

| I spy with my little loupe... upstroke flow ports (arrowed). |

Oddly, I found that the preformed centre hole was a little too tight for the 2mm rod, so I bored it out slighty by hand using one of those mini drill things that come in inkjet refill kits.

With the Goossens spindle ready, I used it as a guide to cut shallow grooves in the brass rod for a pair of securing circlips - a few strokes with the craft saw were all that were required here - then washed off the swarf.

|

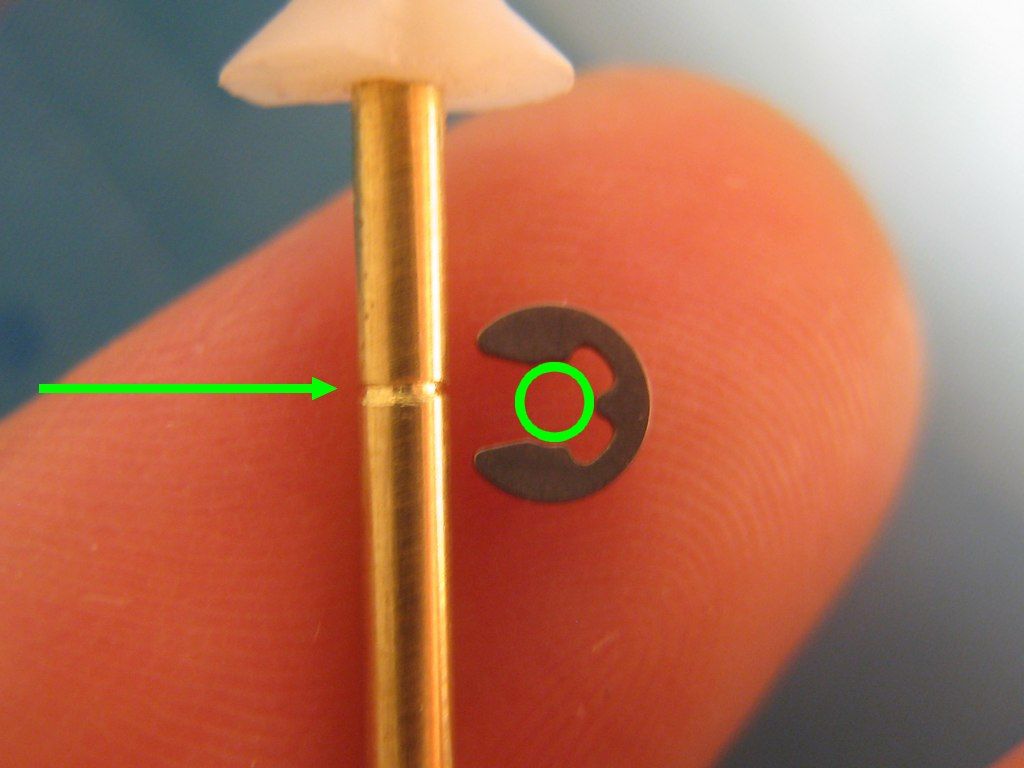

| A groove in the plunger rod, ready for its stainless steel external circlip. |

For the final assembly, I smeared on a little aquarium sealant (there was plenty left over from the 616 vacumatic mods) in the spindle mounting area. The idea was for it to act as a lubricant while pushing the spindle into place, and also to seal any possible weep at this join after curing. I smeared a little over the circlips for good measure too.

|

| The Goossens spindle secured to the brass plunger rod, using stainless steel external circlips above and below. |

Passive Cooling Considerations:

In some single walled pens where the barrel acts as the ink reservoir, heat from the user's hand can expand the air inside the pen. This self-repellence of the caloric encourages the captive aethers to return to the greater firmament, elbowing blobs of ink out of the nib as they rush pell-mell to liberty.

To keep the chaotic forces of nature bridled to Man's bidding, I endeavoured to temper the rate of internal temperature change through the use of a length of solid brass for the control rod, connected directly to the barrel's brass end finial using heatsink paste.

|

| The brass plunger rod & blindcap. |

On the next episode of Flounder's Mindthots...

Shaping the Seals, in which a pair of off-the-shelf rubber seals are tailored to fit the Kaigelu's barrel.

I dont get the heatsink paste, could you clarify?

ReplyDelete