Blind Cap Length

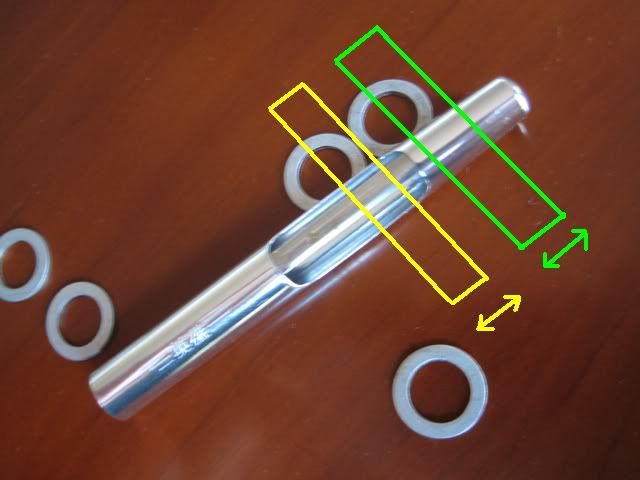

The blind cap could really be cut at any point along the barrel's length without affecting functionality. As a consequence of using the cutting method described in an earlier post, the blind cap was cut unusually long, so that its range of movement is roughly in the yellow area highlighted in the photo below.

If the blind cap were cut shorter - more like the size of most factory fitted fountain pen blind caps - then the range of its movement would be in the green highlighted area of the steel cage. This would look neater, as the ink sac would be completely concealed from every angle, even with the blind cap removed.

If anyone in the UK has a 616 Jumbo ink sac cage/protector going spare, do please contact me using the comment button below this post, or P.M. 'Flounder' on FPN, I'll buy it from you.

Trim Rings

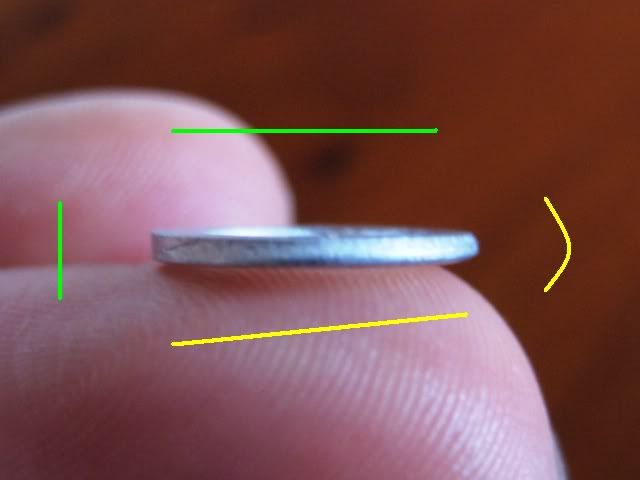

Here's a macro shot of a typical aluminium crush washer from the 10 pack I bought on eBay. I'm sure that they're great in the application they were intended for, but as trim rings, they're less than perfect.

The two faces highlighted in green are pretty much straight and true, while the two faces highlighted in yellow are bowed outward in one case and sloping in the other. This creates problems making the blind cap sit straight with the barrel. I tried to sand the trim rings straight, and it did help, but it's not an ideal situation - an uncalled for extra hurdle.

These crush washers are the only metal washers I could find* with a inner diameter large enough and outer diameter small enough to fit the blind cap in the position it was cut. There would be less of a hassle of the blind cap were cut further up the barrel, where the thicker barrel wall allows a larger range of washers, or if I weren't so averse to cannibalising clutch rings from another 616.

Using a plastic or rubber o-ring would be even cheaper, certainly more symmetrical, and perhaps more in keeping with the 616's Parker 51 style understated aesthetic. If installed on the black model photographed in an earlier post, a black rubber o-ring would be pretty innocuous.

* I've since spotted 10x12 mm shims from internet hobby shops that look promising - google for part number HPI-Z892.

As a parting shot, why don't Parker have a go at manufacturing these - not in another ill-fated attempt at a prestige heritage model, but as a simple, attractive mid level pen that trades on its ancestor's reputation rather than competes with it? Minor 5th Avenue style hood striations would be an inexpensive visual differentiator for those familiar with its heritage, and for new audiences, serve as a tactile reminder of which way round to hold it.

With thicker plastic, a simple cartridge filler, and a modest range of nib sizes, they'd fly off the shelves. They're a far less daunting proposition than open nibbed pens as a transition from ballpoints to fountain pens.

Seasonal tidings of comfort and joy to one and all!

Flounder

No comments:

Post a Comment

Comments seem to be working okay again. You can try leaving one, it might work! If not, you can reach me on twitter if you like @Flounder_FPN